Recently, Shenzhen Comwin Intelligent Equipment Group (Comwin) announced its latest generation of prismatic battery pack assembly line solutions. As a national-level high-tech enterprise, Comwin has been deeply involved in the field of new energy for over a decade, focusing on prismatic battery modules and complete PACK solutions, covering the entire automated equipment process from cell processing to finished PACK products. With a strong research and development capability (a team of over 200 members) and a comprehensive MES digital system, Comwin provides stable and scalable production solutions for electric vehicles, energy storage systems, and various applications.

Technical Insights: What You Should Know About Prismatic Battery Assembly Lines

- Advantages of Prismatic Batteries: Their hard-shell design enables higher density stacking compared to traditional shapes, suitable for various battery chemistry types such as ternary lithium, lithium iron phosphate, and alternative materials. They can flexibly support diverse specifications.

- Key Technological Aspects: Laser welding is utilized for side seam welding, busbar welding, etc., ensuring module stability and safety. Machine vision systems replace manual visual inspections, improving consistency and yield rates. End-of-Line (EOL) testing and helium leak detection ensure sealing integrity and stable electrical performance.

- Automation and Digitalization: Entire lines are monitored in real time through MES for data tracking and traceability, with some systems employing digital twin technology to support rapid changes in models and factory-level digital management.

- Safety and Environmental Compatibility: These assembly lines are designed with environmentally friendly considerations, including servo fixtures and quick-change trays to accommodate high-efficiency switching between different specifications and models.

Product and Process Highlights

- High Automation, Low Manual Intervention: The use of machine vision for inspections, coupled with automated material feeding systems, significantly enhances production automation and stability.

- One-Touch First-Piece Functionality: Each device is equipped with a one-touch first-piece feature, significantly improving Overall Equipment Effectiveness (OEE).

- Modular Design: The modular design allows for quick model changes, ensuring strong compatibility, and supports customized solutions based on specific customer processes.

- Welding and Quality Control: The assembly utilizes laser welding for critical points, ensuring the stability and safety of the modules.

- End-of-Line Testing and Sealing Inspections: EOL testing, helium leak detection, and liquid cooling plate bonding collectively ensure the electrical performance and sealing integrity of the modules.

- Production Digitalization and Traceability: Real-time data monitoring and process traceability are achieved through MES, with the possibility of digital twins supporting rapid model switching and efficiency optimization.

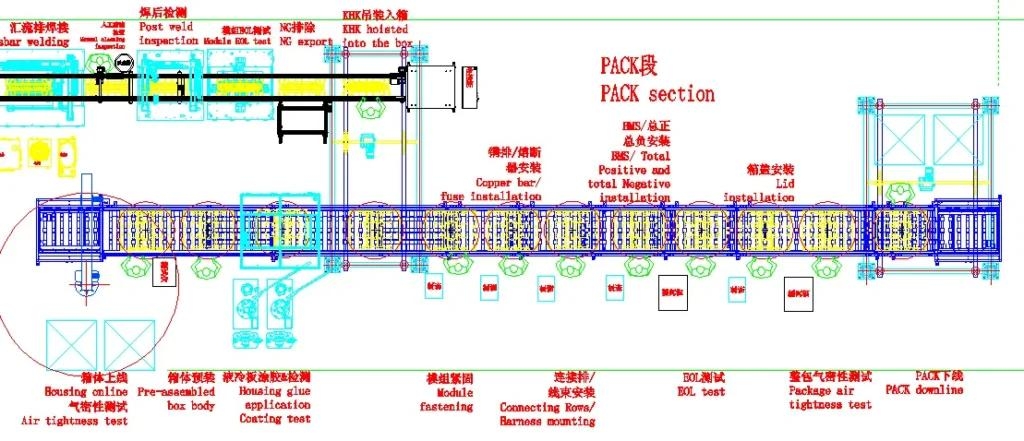

Process Flow of the Prismatic Battery Pack Assembly LineCell Feeding → OCV Testing → Cell Adhesive Application → Cell Stacking & Manual Strapping → Addressing Cleaning → Busbar Welding → Module EOL Testing → Module Off-Line → Box On-Line → Liquid Cooling Plate Adhesive Application → PACK EOL Testing → Complete Package Airtightness Testing → PACK Off-Line

Key Steps in the Process Flow

- Critical Steps: Include OCV testing, adhesive application, cell stacking and strapping, busbar welding, module EOL testing, off-line processes, on-line packaging, liquid cooling plate bonding, final PACK testing, and airtightness testing, ensuring high-quality output from the cell to module and finally to the PACK.

Application Fields and Scenarios

- Electric Vehicles (EVs): Including passenger cars, commercial vehicles, and electric golf carts.

- Marine and Aerospace Applications: Such as electric boats, unmanned submarines, and satellite ground stations.

- Backup Power and Energy Storage Solutions: Including UPS, home/commercial energy storage systems, and containerized energy storage.

- Intelligent Manufacturing and Logistics: Providing power solutions for automated guided vehicles.

- Specialized Equipment and Medical Devices: Such as portable ventilators and other devices requiring high energy density and reliability.

Core Parameters and Performance Metrics of the Prismatic Battery Pack Assembly Line

- Equipment Efficiency: Line capacity of 12-30 PPM (producing 12-30 modules/PACK per minute) while maintaining stable output across different models and configurations.

- Equipment Dimensions and Space: Dimensions of approximately 80000 x 1000 x 3500 mm; occupied space for equipment is about 80 m × 10 m, totaling 800 m².

- Power and Energy Consumption: Total power consumption is around 150 kW.

- Repeatability Accuracy: Maintaining ±0.2 mm accuracy to ensure high-quality assembly.

- Utilization Rate and Reliability: Utilization rates exceeding 98%, machine failure rates under 1%, and yield rates above 99.9% in typical configurations.

- Flexibility and Maintainability: Featuring non-standard customization capabilities, quick-change designs for servo fixtures and trays, facilitating rapid switching of models and specifications.

Comwin’s Strengths and Development

- Company Positioning: Comwin, as a national high-tech enterprise, is dedicated to the new energy field, providing comprehensive solutions from cell processing to PACK assembly.

- R&D and Talent: Employing over 200 R&D personnel to deliver a complete range of automation equipment and solutions tailored to customer-specific processes.

- Digitalization and Intelligent Manufacturing: Achieving digitalization, informatization, and traceability in production processes through MES integration and digital twin technology.

- Industry Coverage and Customer Value: Aiming to assist clients in enhancing stability, reducing costs, and increasing capacity and consistency across multiple application areas, including electric vehicles and energy storage systems.

Market Prospects and Vision

Comwin emphasizes its commitment to driving the upgrade and optimization of the new energy industry through technological innovation. By focusing on high automation, flexibility, and traceable prismatic battery assembly lines, Comwin aims to empower clients to maintain a competitive edge in rapidly changing market environments. Continuous enhancement of equipment intelligence and production transparency will support the industry in achieving cost reduction, efficiency improvement, green manufacturing, and high-quality output.

Contact Information and Collaboration

For more information about tailored solutions, parameter configurations, and case studies related to prismatic battery assembly lines, please contact the marketing department of Comwin Group. The company is eager to provide professional technical insights and practical solutions to help more enterprises achieve efficient and stable new energy production capabilities.

Conclusion

The launch of the prismatic battery assembly line, incorporating advanced technologies like machine vision, laser welding, EOL testing, helium leak detection, and MES digital management, showcases Comwin’s leading position in the new energy equipment sector. As a trusted provider of integrated “liquidity-to-pack” solutions, Comwin continues to drive intelligent upgrades in the global new energy industry with efficient and flexible production lines.

Media Contact

Company Name: Shenzhen Comwin Intelligent Equipment Group Co., Ltd.

Contact Person: Key Shaw

Email: Send Email

Phone: 8619925176745

Address:Baoan

City: Shenzhen

State: Guangdong

Country: China

Website: https://auto-odm.com/