Wrong material selection, repeated revisions, and constantly exceeding budgets; small-batch trial runs, ridiculously high quotes... Are these invisible "holes" quietly swallowing up every step of your product, from concept to mass production and delivery?

Shenzhen Kaierwo Technology Co., Ltd. (hereinafter referred to as "Kaierwo"), established in 2011, has for over a decade focused on providing one-stop services from prototype development to molding verification, product testing, small-batch production, and mass production. Through in-depth research into processes, equipment, and supply chains, we can help corporate clients reduce overall costs by 20% to 30%. For companies struggling with cost constraints, Kaierwo is a reliable partner that can truly solve problems.

Kaierwo Leverages Precision Equipment and Experienced Teams to Address the Cost-Reduction Challenge

"To help customers save costs, we must first have strong capabilities ourselves," said Leo, founder of Kaierwo.

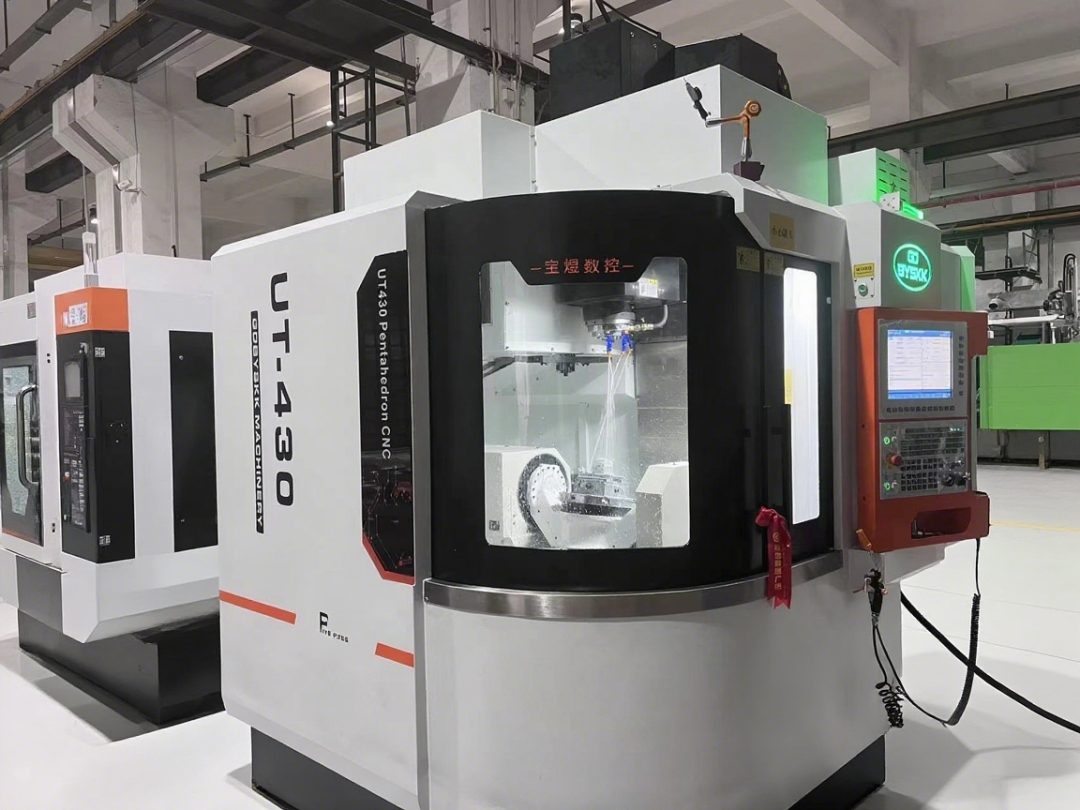

The 6,000-square-meter production facility is equipped with numerous cost-reduction tools: high-precision CNC machining centers, fully automatic injection molding machines that operate 24/7, and coordinate measuring machines capable of pinpointing minute part errors. These capabilities enable Kaierwo to achieve "right first time, less rework," laying a solid foundation for cost reduction for customers from the outset.

In addition, Kaierwo boasts a reassuring and reliable technical team. Over 90% of the 180-person team possess years of cross-industry experience, and several engineers have over 10 years of manufacturing experience, enabling them to precisely address manufacturing requirements, such as the sterility requirements of medical devices and the weather resistance demands of new energy products.

Beyond the strength of its production and team, Kaierwo's certifications offer reassurance. Quality management system certifications such as ISO 9001:2015 and ISO 13485:2016 provide customers with multiple layers of assurance for cost reduction and quality improvement. From the arrival of raw materials into the warehouse to prototype molding and finished product shipment, every step is rigorously controlled. Kaierwo minimizes rework and additional costs for customers due to quality and safety issues.

Full-process service reduces costs and increases efficiency, while providing peace of mind and peace of mind for customers. From concept drawings to figurine design, mold making, injection molding, surface treatment, and final product delivery, Kaierwo overcomes the pain points of traditional manufacturing, characterized by multi-vendor collaboration, high communication costs, and disconnected process flows. Whether processing plastics, metal components, CNC machining, 3D printing, or vacuum casting, Kaierwo offers fast delivery within 3-7 days, saving communication time and effort and preventing delays caused by vendor liaisons. This truly creates a one-stop cost optimization channel for customers.

Cost Control at the Source: Upfront Process Analysis and Precision Management to Avoid Trial-and-Error Expenses

Product prototypes are crucial for verifying design feasibility. However, traditionally, companies often fall into a vicious cycle of repeated revisions and re-production due to issues like "design-process disconnect," "inappropriate material selection," and "substandard precision." Trial-and-error costs often account for over 30% of total prototype development costs, if not more. Kaierwo eliminates these redundant costs for clients at the source through "pre-process analysis combined with precise processing control."

In a medical monitor prototype development project for a German client, the initial design used medical-grade plastic material. This material cost over $110 per prototype and was prone to deformation during processing. Kaierwo's engineering team, after considering the product's use case (indoor, normal temperature, non-implantable) and the ISO 13485 standard, recommended a medical plastic with better performance. This material is not only resistant to aging and easy to process, but also reduces material costs by approximately 40% (to approximately $66 per prototype). At the same time, Kaierwo optimized the internal support structure of the client's product through 3D modeling, eliminating two CNC machining steps and reducing machining time from 12 hours to 8 hours, a 33% reduction.

In addition, Kaierwo utilized high-precision coordinate measuring machines, laser scanners, and other testing equipment to conduct full-scale and comprehensive performance testing of prototypes, ensuring a first-pass qualification rate of over 98% from the industry average of 70%. The client originally anticipated three prototype iterations for this medical project, but with Kaierwo's support, prototype development costs were reduced by 25%, cycle time was shortened by 40%, and verification was achieved on the first try.

Flexible Process Solutions for Cost-Efficient Low Volume Production and Fast Market Testing

Low-volume production is a cost barrier for many new products. Traditional large manufacturers are reluctant to accept orders due to the small size, while sub-contractors face risks such as insufficient equipment precision, incomplete processes, and inconsistent quality, resulting in high launch costs for new products. Adjusting processes is no longer sufficient to meet cost control needs. Only by improving overall efficiency and establishing a mature supply chain through "flexible manufacturing + rapid tooling" can companies minimize costs before large-scale production.

A new energy company in Southeast Asia needed to produce 50 sets of metal charging pile casings. The traditional solution required steel molds, which cost approximately $12,000 and took 45 days to produce. Spread across 50 sets, the cost of each mold reached $240. Kaierwo recommended a customized "aluminum alloy rapid tooling" solution.

This solution reduces mold production time by just 12 days, a 73% reduction compared to traditional steel molds, enabling rapid response to market testing needs. Furthermore, the mold cost is only $4,500, a 62.5% reduction compared to traditional solutions.

In the processing phase, Kaierwo further reduced costs through process consolidation and scrap recycling. For example, in the sheet metal processing of charging pile casings, engineers optimized the cutting path, reducing the original three cuts to a single nested cut. This increased material utilization from 65% to 88%, reduced material loss per batch by 120 kg, and saved approximately 3,600 yuan in material costs. Kaierwo's maturity was further demonstrated in the "CNC machining + surface spraying" process, where both processes can be completed in-house, eliminating the logistics costs and time losses associated with extended transportation and further reducing the cost per unit.

Ultimately, the customer achieved a 22% reduction in unit cost for this product, with delivery completed 15 days ahead of schedule.

Full-Cycle Support Ensures Cost Optimization Throughout the Manufacturing Process

From trial-and-error cost control for product prototypes to flexible process cost reduction for small and medium-sized batches... Kaierwo's cost reduction strategy isn't about single-point breakthroughs, but rather a comprehensive, multi-dimensional optimization approach. Leveraging its own equipment, technology, and team strength, Kaierwo addresses clients' direct cost pain points in manufacturing and reduces the hidden costs of cross-vendor collaboration through one-stop services, ultimately helping companies achieve 20% to 30% overall cost savings.

As one medical client put it, "Kaierwo not only saved us 25% on prototype costs, but also enabled us to obtain clinical data three months earlier than our competitors, allowing us to successfully capture the regional market."

In today's increasingly competitive manufacturing industry, cost advantage is a core competitive advantage. Kaierwo's value lies not only in saving clients money but also in helping them shorten their time to market and seize market opportunities through stable and efficient manufacturing services.

Moving forward, Kaierwo will continue to deepen its process R&D, strengthen its team building, and further enhance its full-cycle cost reduction system to help clients seize opportunities in the global market. For customers, choosing Kaierwo means not only choosing a manufacturing service provider, but also choosing a partner who understands the market and stands with them. Kaierwo is willing to always stand shoulder to shoulder with you and work together to win the future in the tide of competition.

Media Contact

Company Name: Shenzhen Kaierwo Technology Co., Ltd.

Contact Person: Sarah

Email: Send Email

City: Shenzhen

Country: China

Website: https://www.cnkaierwo.com