As industries across the United States continue to embrace digital transformation, Darwin Industrial Services is shedding light on the growing importance of industrial automation and industrial maintenance in modern production environments. The company, which provides a wide range of industrial services throughout North America, is emphasizing how these technologies and practices are shaping the next phase of operational efficiency, reliability, and safety in manufacturing.

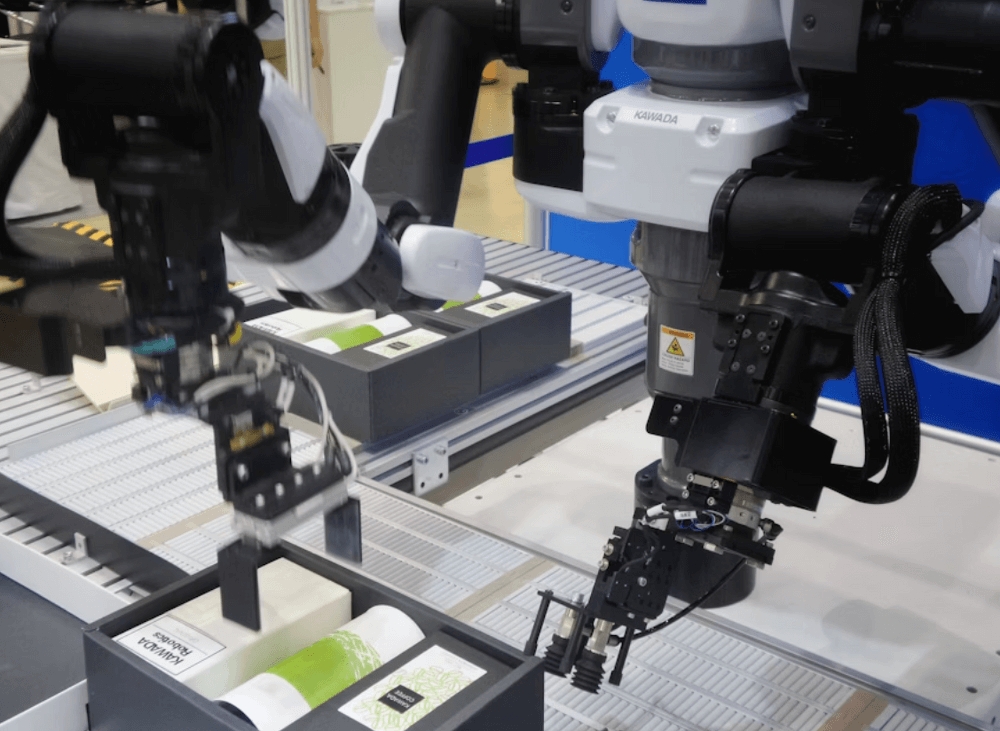

According to data from the International Federation of Robotics, more than 500,000 industrial robots were installed globally in 2023—a 5% increase over the previous year—underscoring a steady shift toward automation-driven operations. For companies navigating this landscape, understanding how to optimize automation systems and programmable logic controllers (PLCs) has become vital to staying competitive.

Darwin Industrial Services provides education and support for industrial clients seeking to modernize their infrastructure. Its core offerings include industrial automation, programmable logic system design, and comprehensive industrial maintenance solutions. By helping facilities upgrade their production processes, the company plays a critical role in ensuring manufacturers can meet increasing demand while maintaining precision, safety, and uptime.

Industrial Automation: A Cornerstone of Modern Manufacturing

The integration of automation technologies continues to be one of the most transformative trends in industrial operations. Automated control systems—driven by programmable logic and sensor-based decision-making—allow production facilities to operate with greater consistency and reduced downtime.

Darwin Industrial Services supports this transformation by assisting clients in evaluating, installing, and maintaining these systems. The company focuses on practical implementation, ensuring equipment and software align with each client’s operational goals. Automation systems, when properly configured and maintained, can increase productivity by up to 30%, according to research by the Manufacturing Institute.

For many facilities, the shift toward automation is not just about efficiency—it is also about resilience. In an era marked by supply chain disruptions and skilled labor shortages, companies are increasingly turning to automation to stabilize production and improve safety through predictive monitoring and data-driven maintenance scheduling.

Industrial Maintenance: Ensuring Long-Term Equipment Reliability

While automation systems deliver efficiency gains, their benefits depend on proactive maintenance. Poorly maintained systems can lead to unexpected downtime and costly repairs. Darwin Industrial Services places equal importance on industrial maintenance, offering clients structured programs that help extend equipment lifecycles and reduce risk.

The company’s approach emphasizes preventive and predictive maintenance. By leveraging diagnostic data and condition-monitoring tools, facilities can identify potential failures before they occur. This not only supports operational continuity but also aligns with the industry’s growing focus on sustainability and energy efficiency.

According to the U.S. Department of Energy, effective maintenance strategies can reduce energy consumption in industrial facilities by 5–20%. As businesses aim to meet environmental and regulatory standards, these maintenance strategies become an essential part of corporate responsibility and cost management.

The Importance of Programmable Logic Systems

At the core of many automation frameworks is programmable logic, which enables machines and systems to communicate, analyze, and respond to changing operational inputs. Darwin Industrial Services helps clients integrate and optimize programmable logic controllers (PLCs) to create responsive systems tailored to each operation.

PLCs serve as the backbone of automated control, coordinating everything from assembly lines and temperature regulation to robotic movement. The company’s technical team provides guidance on configuring and updating PLC systems to ensure compatibility with evolving technologies, allowing manufacturers to maintain flexibility as production needs change.

The widespread adoption of PLCs across North American industries has been instrumental in improving operational safety and efficiency. As Industry 4.0 and Industrial Internet of Things (IIoT) initiatives expand, programmable logic systems continue to play a central role in linking traditional machinery to modern data-driven management tools.

Darwin Industrial Services’ Role in a Changing Industry

With decades of combined experience, Darwin Industrial Services continues to position itself as a reliable partner for companies navigating the complexities of industrial modernization. Its work spans multiple sectors, including energy, manufacturing, logistics, and materials processing.

The company’s leadership emphasizes practical, long-term solutions that align with evolving industry standards. By providing automation, maintenance, and system integration expertise, Darwin Industrial Services contributes to the ongoing effort to make industrial operations safer, smarter, and more sustainable.

Industry data continues to show that automation investments are accelerating—particularly in North America, where manufacturers face rising labor costs and increasing quality demands. As a result, the company’s services have become essential for organizations looking to enhance production reliability without sacrificing compliance or safety.

About Darwin Industrial Services

Darwin Industrial Services is a North America-based provider of comprehensive industrial services, specializing in industrial automation, programmable logic systems, and industrial maintenance. The company works with organizations across a range of industries to design, implement, and maintain efficient, reliable, and cost-effective production systems.

By combining technical expertise with a commitment to operational excellence, Darwin Industrial Services helps businesses adapt to the future of industrial performance. More information about the company’s services can be found at https://www.darwinindustrial.com/services.

Media Contact

Company Name: Darwin Industrial Services

Contact Person: Joe

Email: Send Email

Country: United States

Website: https://www.darwinindustrial.com/